We are a full-service enterprise integrating plastic sheet manufacturing, professional vacuum forming, and high-precision post-processing, offering end-to-end solutions for customers across industries. From raw plastic sheet production to custom-formed components and finished precision parts, we cover every link of the value chain, ensuring consistency in quality, efficiency in delivery, and cost-effectiveness in pricing.

1. Plastic Sheet Manufacturer: High-Quality, Factory-Direct Supply

As a professional plastic sheet manufacturer, we pride ourselves on a diverse range of products and robust production capabilities, meeting both standard and custom needs:

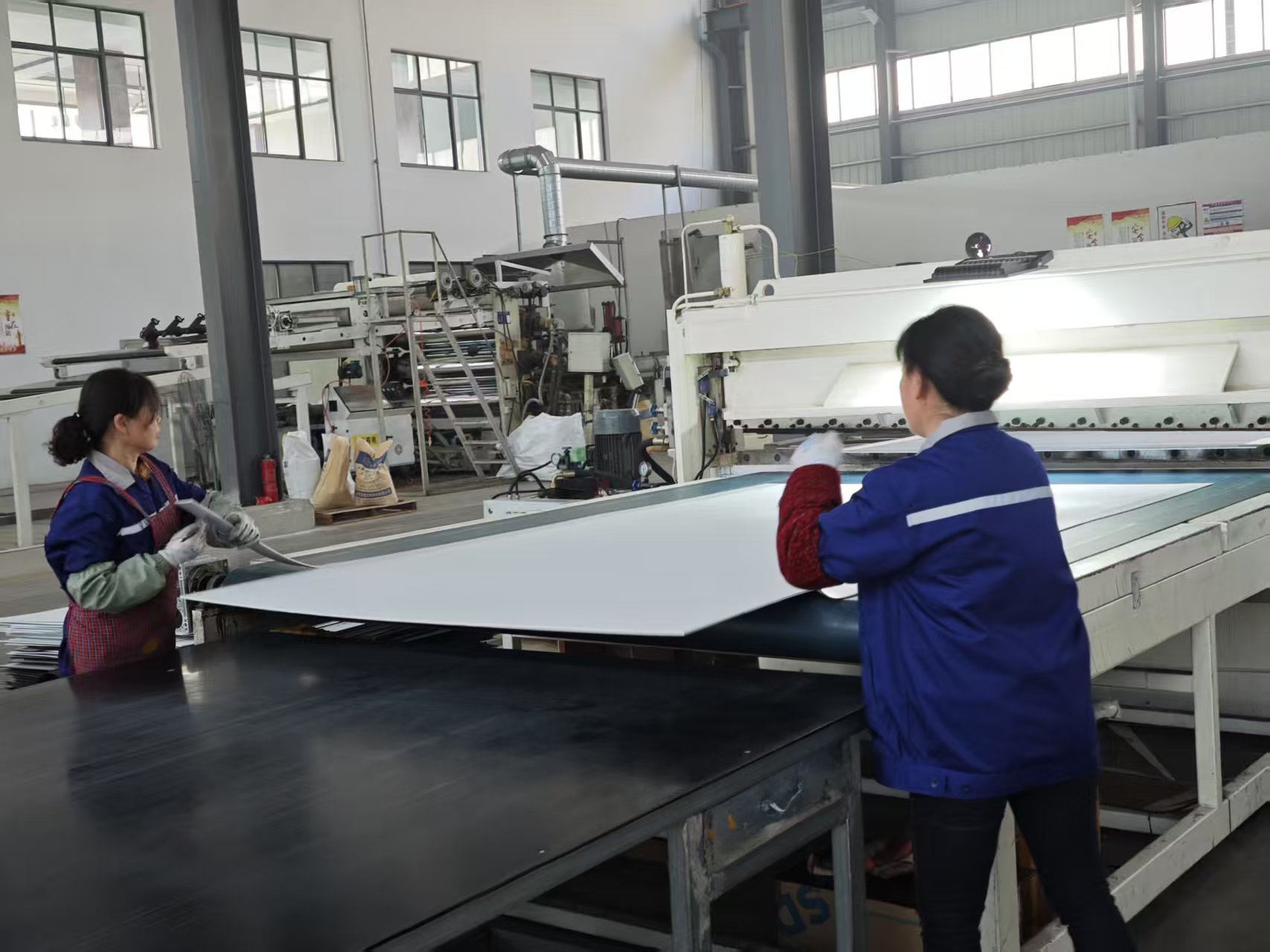

Rich Product Portfolio: We produce a wide variety of plastic sheets and panels, available in a full spectrum of colors. Our sheets excel in key performance metrics, including excellent processability, cold resistance, high-temperature tolerance, impact resistance, antistatic properties, and flame retardancy—making them suitable for industries like automotive, home appliances, electronics, and construction.

Factory-Direct Advantages: As a direct manufacturing facility, we eliminate middlemen markups, enabling us to offer competitive prices while strictly guaranteeing product quality. We welcome custom sample requests and can tailor sheets to your specific requirements (e.g., color, texture, dimensions) to match your application scenarios.

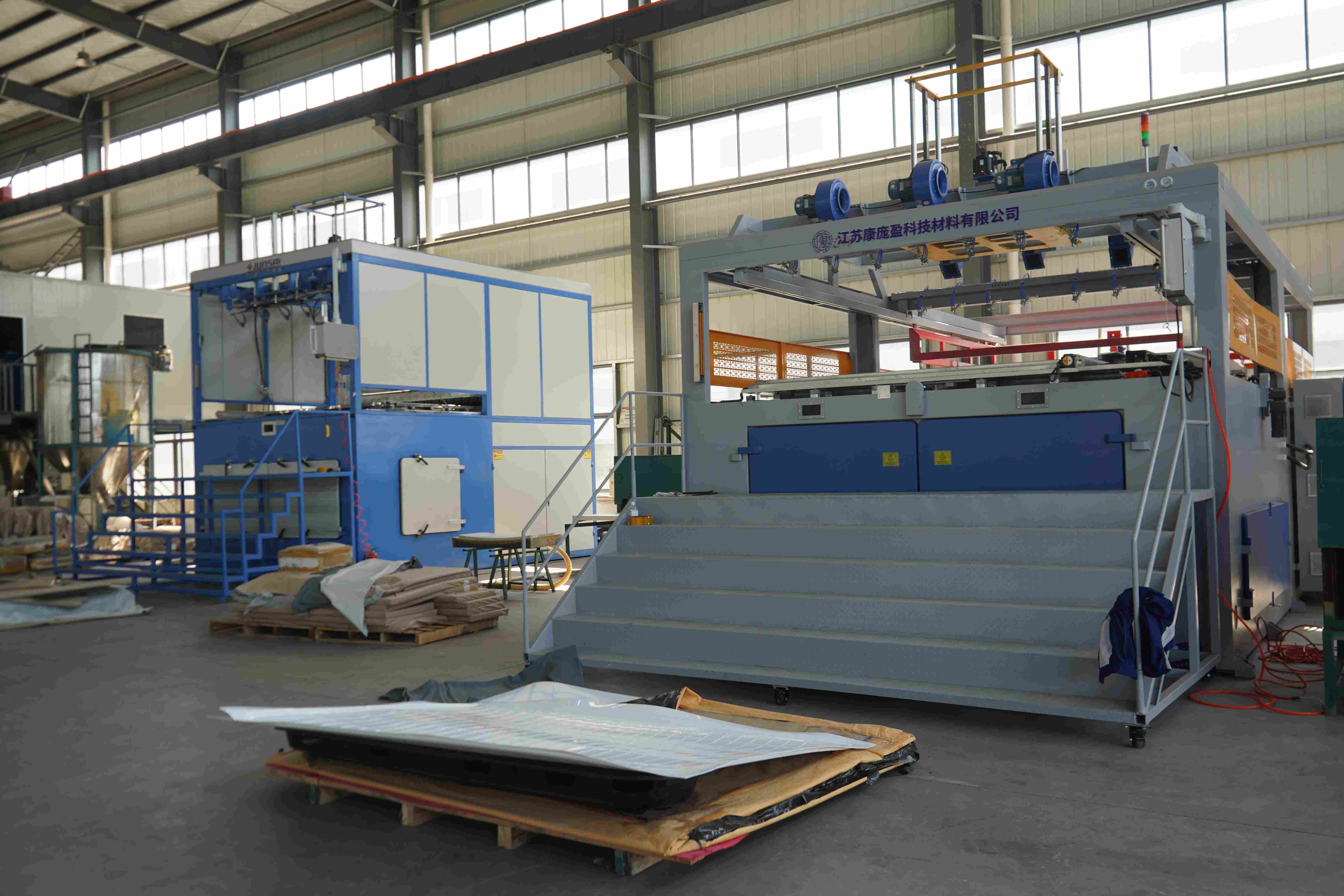

Strong Production Capacity: Equipped with 8 production lines in total—including 6 international standard co-extrusion lines—our annual production capacity reaches 24,000 tons. This scale ensures fast delivery, even for large-volume orders, effectively supporting your project timelines.

2. Vacuum Forming Service Provider: 18+ Years of Expertise in Custom Solutions

With over 18 years of professional experience, we stand as a leading vacuum forming manufacturer, specializing in turning plastic materials (including our own sheets or customer-specified materials) into high-quality custom components:

End-to-End Solutions: We offer integrated services covering OEM vacuum forming parts and precision engineered components, streamlining every stage from initial design and prototyping to mass production and delivery. This one-stop approach reduces communication costs and shortens project cycles for our clients.

Stringent Quality Control: We implement rigorous quality checks at every step—from material selection (ensuring compatibility with forming processes) and mold development (optimizing for precision) to surface treatment (enhancing durability and aesthetics). This commitment guarantees consistent excellence in every formed part.

Flexible Production Capabilities: Whether you need small-batch prototypes for product testing or large-scale production for market launch, we adapt to your volume needs. By combining technological innovation with efficient workflows, we deliver faster turnaround times and cost-effective solutions without compromising reliability.

3. 5-Axis CNC Engraving: Comprehensive Post-Forming Finishing

To complement our vacuum forming services, we provide full-range post-processing solutions using state-of-the-art 5-axis CNC engraving machines, transforming formed plastic parts into precision-ready components:

High-Precision Machining: Our 5-axis CNC engraving equipment enables intricate processing tasks, including complex engraving, clean edge trimming, dimensional drilling, and precise contour cutting of parts with complex geometries. This level of precision ensures parts fit perfectly into your final assemblies.

Full-Spectrum Finishing Services: Beyond machining, we offer detailed surface treatments (e.g., smoothing, deburring), custom texture development, and professional painting. Every step is designed to meet strict aesthetic and functional standards, ensuring the final part not only performs well but also meets your visual requirements.

Seamless Integration with Vacuum Forming: We handle every critical step from vacuum forming output to finished components—taking care of trimming, refining, and coating before product integration. This end-to-end processing eliminates the need for you to coordinate multiple vendors, simplifying your supply chain.

Guided by a focus on quality, efficiency, and customer-centricity, we are dedicated to becoming your trusted partner for all plastic-related manufacturing needs. Whether you require raw sheets, custom vacuum-formed parts, or fully finished precision components, we have the expertise and capacity to deliver solutions that align with your goals.