PVC ABS Sheet

PVC ABS Sheet is a high-performance composite material engineered by combining the exceptional flame retardancy and chemical resistance of Polyvinyl Chloride (PVC) with the superior impact strength and rigidity of Acrylonitrile Butadiene Styrene (ABS). This unique fusion creates a versatile and safety-compliant material ideal for applications where fire safety, durability, and chemical stability are non-negotiable.

Introduction:

PVC ABS Sheet is a high-performance composite material engineered by combining the exceptional flame retardancy and chemical resistance of Polyvinyl Chloride (PVC) with the superior impact strength and rigidity of Acrylonitrile Butadiene Styrene (ABS). This unique fusion creates a versatile and safety-compliant material ideal for applications where fire safety, durability, and chemical stability are non-negotiable.

Key Features & Benefits:

Inherent Flame Retardancy: The PVC component provides excellent inherent flame resistance, typically achieving a UL 94 V-0 rating, making it a safe choice for enclosed spaces and electrical applications.

Superior Chemical Resistance: Highly resistant to a wide range of acids, alkalis, oils, and cleaning agents, ensuring long-term performance in corrosive environments.

Excellent Rigidity and Impact Strength: The ABS core contributes outstanding structural strength and toughness, making the sheet durable and resistant to impacts and cracks.

High Dielectric Strength: Offers excellent electrical insulation properties, suitable for various electrical and electronic applications.

Easy Fabrication: Can be easily machined, routed, sawed, and thermoformed using standard woodworking and plastic fabrication equipment.

Cost-Effective Safety Solution: Provides a more impact-resistant and rigid alternative to solid PVC and a more flame-retardant alternative to standard ABS at a competitive price point.

Technical Specifications (Typical):

Composition: Co-extruded or laminated PVC + ABS

Available Thickness: 1mm - 5mm

Standard Sheet Sizes: 4x8 ft, 5x10 ft (Custom sizes available)

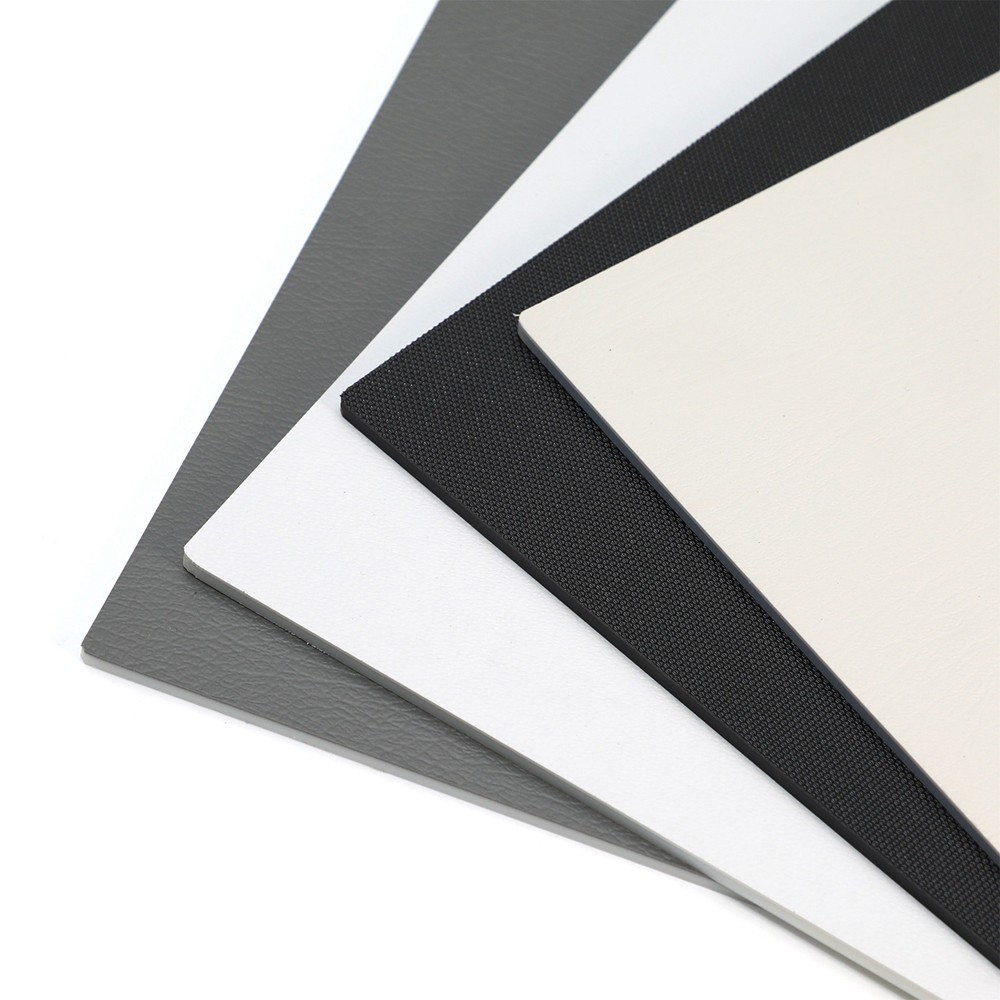

Surface Finish: Smooth, Matte, Embossed

Flame Rating: UL 94 V-0 (Standard)

Colors: White, Grey, Black (Custom colors available)

Primary Applications:

Electrical Enclosures: Housings for switches, control panels, circuit breakers, and electrical cabinets.

Public Transportation & Mass Transit: Interior wall and ceiling panels, partition walls, and seating components for buses, trains, and subways.

Building & Construction: Interior partitions, wall cladding, and fixtures in hospitals, schools, and commercial buildings where flame spread is a concern.

Chemical Industry: Tanks, fume hoods, and work surfaces resistant to chemical splashes.

Material Handling: Chutes, hoppers, and trays for industrial applications.

Conclusion:

PVC ABS Sheet is the definitive choice for engineers and designers who need a material that reliably meets stringent safety standards without compromising on mechanical performance or chemical resilience. It delivers critical protection and peace of mind for demanding indoor and industrial environments.